Onewheel operates in harsh environment, vibrations, shocks, sometimes it rolls on the ground, to make a reliable external battery for onewheel, it calls for a strong casing.

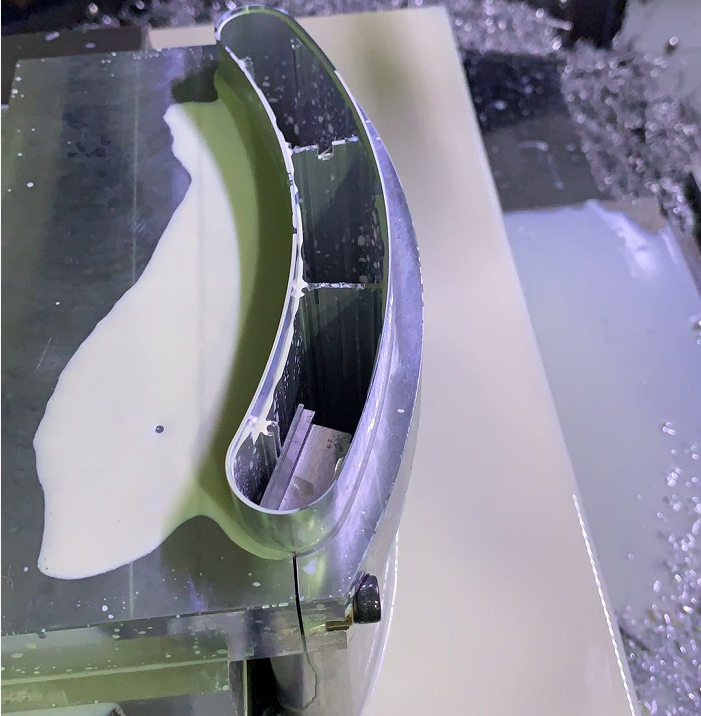

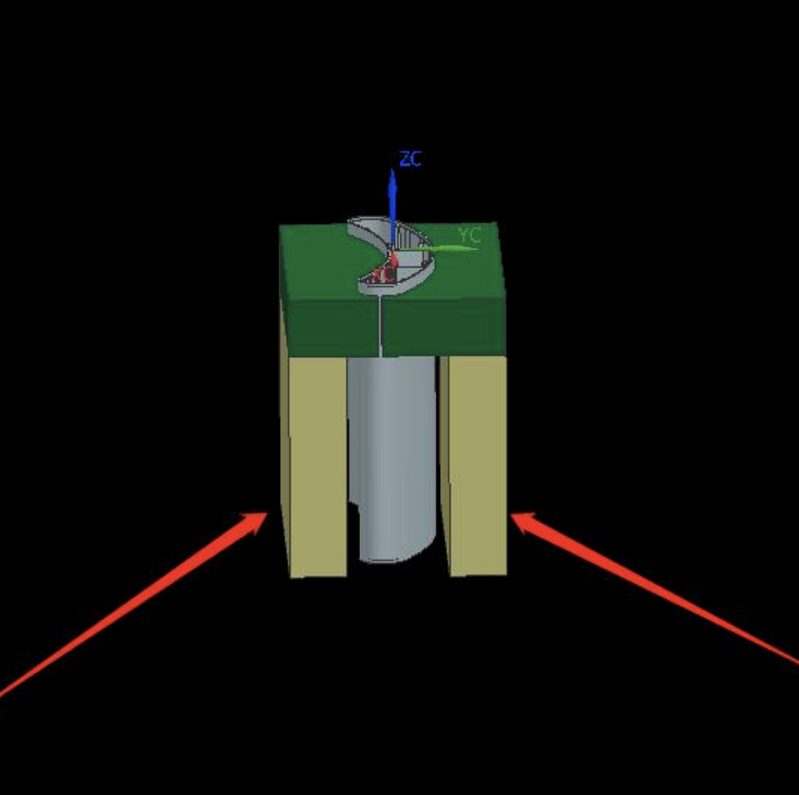

To fit on the top of the fender, we designed the aluminum body to have a curvature, with pocket inside to firmly hold the cells inside, the body is pushed out of a die and extruded into this shape, with the wall thickness of 2mm, coupled with ribs inside, it can take a hard hit and remain its structural integrity.

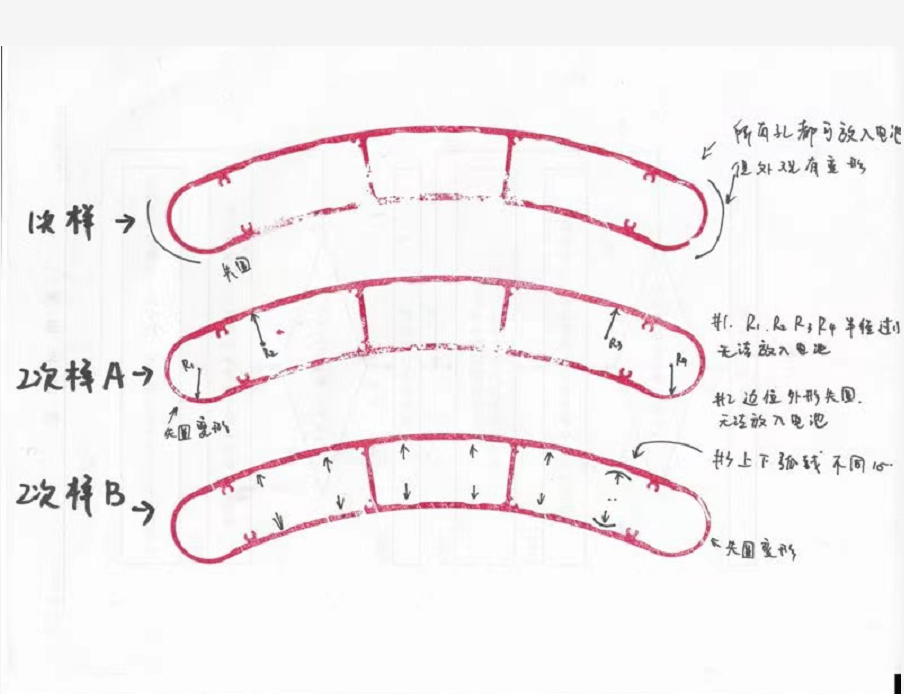

The extrusion of this body was not easy to make, to be honest, we failed 3 times, and after 9 months of trying, we finally got it to produce stable extrusion that fits for CNC machining.

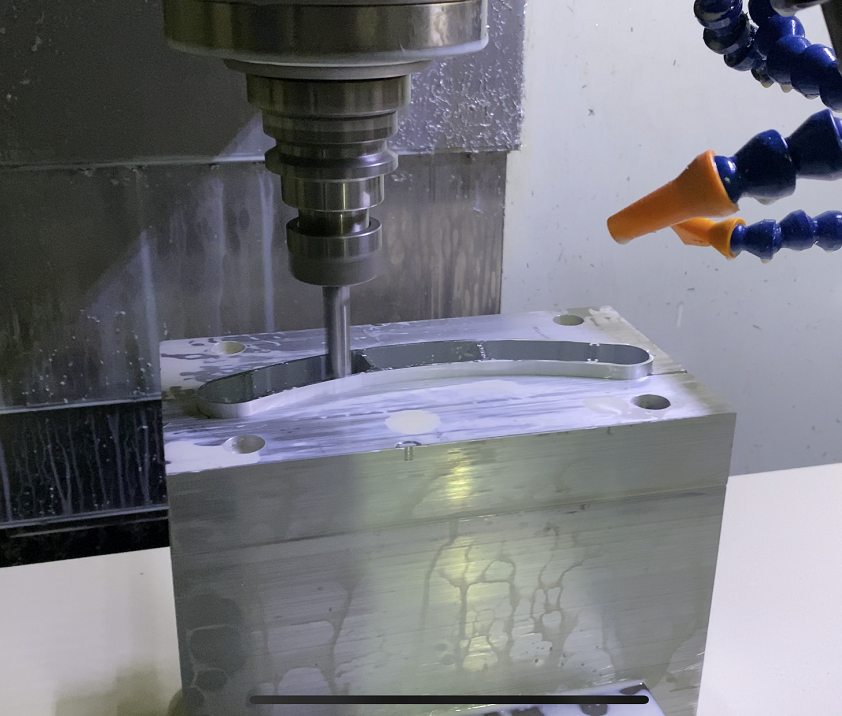

CNC machining, how hard can it be? It turns out to be a headache as well, due to its shape, it was difficult to clamp it on the bed of CNC machine, we tried several different method and landed on this fixture that has 2 thick walls and jaws to clamp it using a pricision vise.